Do you really understand OCA Optically Clear Adhesive?

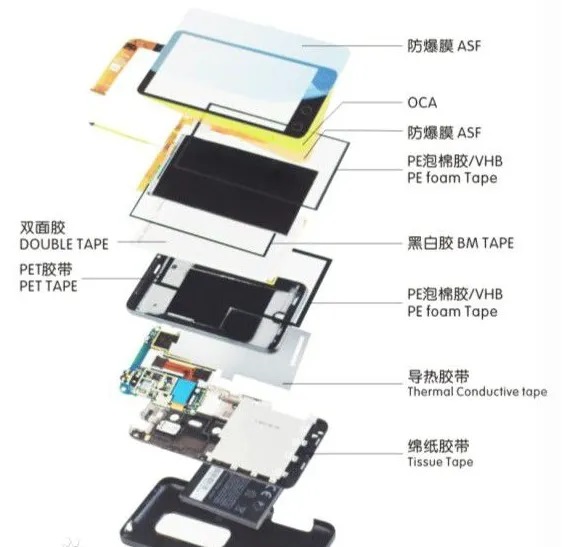

1. What is OCA?

OCA (Optically Clear Adhesive) is one of the raw materials of TFT touch screen. It is made of optical acrylic pressure-sensitive adhesive without substrate, and then a layer of optical release film is attached to the upper and lower bottom layers to make a double-sided adhesive tape. A double-sided adhesive tape without matrix material; OCA has the advantages of high cleanliness, high light transmittance, low haze, high adhesion, no crystal points, no bubbles, water resistance, high temperature resistance, UV resistance, etc. , And its thickness is uniform and flat, and the refractive index of OCA is close to that of glass, PC, and PMMA. Long-term use will not cause problems such as yellowing, aging, fogging, detachment from the adhered surface, and bubbles.

All in all, it is the material used to make Touch Panle.

2. how to distinguish good or bad quality OCA?

Good quality OCA has this effect:

1). Can reduce glare, reduce the loss of light emitted by the LCD or Mini OLED display, increase the brightness of the display and provide high transmittance, and reduce energy consumption;

2). Increase the contrast, especially the contrast under strong light; the surface connection has a higher intensity;

3). Avoid Newton’s ring;

4). The surface of the product is smoother without wrinkles, bubbles, impurities, and the display image has almost no effect through OCA optical adhesive.

5). No borders, expand the visible area; good defoaming effect, high yield of TFT touch screen, no yellowing, good rework.

The poor quality OCA is like this:

1). The process of gluing is prone to dead bubbles and cannot be defoamed.

2). After sticking the glue and removing the bubbles, it is easy to cause the bubbles to rebound. Rework is required, which takes time and cost.

3). The glue is prone to yellowing after being used for a period of time.

4). Imprinting will occur when the protective film of the adhesive is peeled off. There will be residual greasy glue and asymmetry around.

All in all, we should pay attention to the following points in the process of purchasing OCA dry glue:

Focus on checking whether there are indentation (the material does not allow joints), creases, white spots, foreign objects, pinholes, depressions, bubbles, glue wrinkles.

3. OCA processing technology:

OCA die-cutting processing plants generally use optical adhesive die-cutting technology, optical adhesive product perforation and sleeve hole technology, optical adhesive linear bubble position adjustment technology; by purchasing OCA optical collagen material, and then according to different customers Combine the process for OCA structure design, precision die cutting or slitting and other preliminary processing and sell it to the assembly plant of the touch screen or display module. Downstream manufacturers establish more comprehensive and close ties.

And according to the different full-fitting processes of different customers, OCA structure design and precision die cutting are carried out after initial processing such as slitting